📐 Design Requirements

This project began with a simple requirement: to build a sturdy, minimal, non-toxic bed frame for a 1400mm x 2000mm IKEA ÅFJÄLL foam mattress. I aimed to size the frame close to queen dimensions — around 1530mm wide and 2030mm long — while ensuring it stayed within an acceptable range of 1500–1800mm width and 2000–2400mm length. The goal was to keep the design grounded, aesthetically simple, and free from metal fasteners, paint, or toxic finishes.

🧪 Exploring Concepts

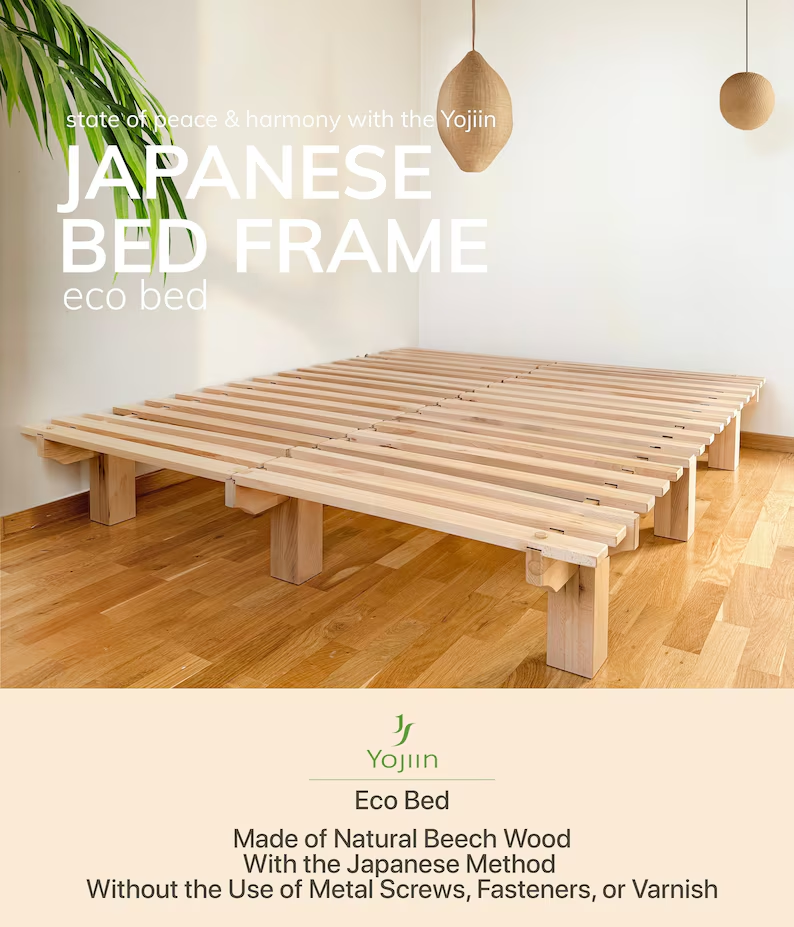

Option 1: Japanese Bed Frame

First, I began exploring Japanese platform bed designs — clean lines, low profile, no visible screws. One specific listing from Etsy inspired me. It used beech wood and featured nine legs at 30–33cm high, spaced to provide full mattress support. I calculated that I’d need materials like 90x90mm laminated pine for the legs and 184x19mm pine for the frame. Add slats cut from 140x19mm DAR pine, and the total approached $488, including tung oil for finishing.

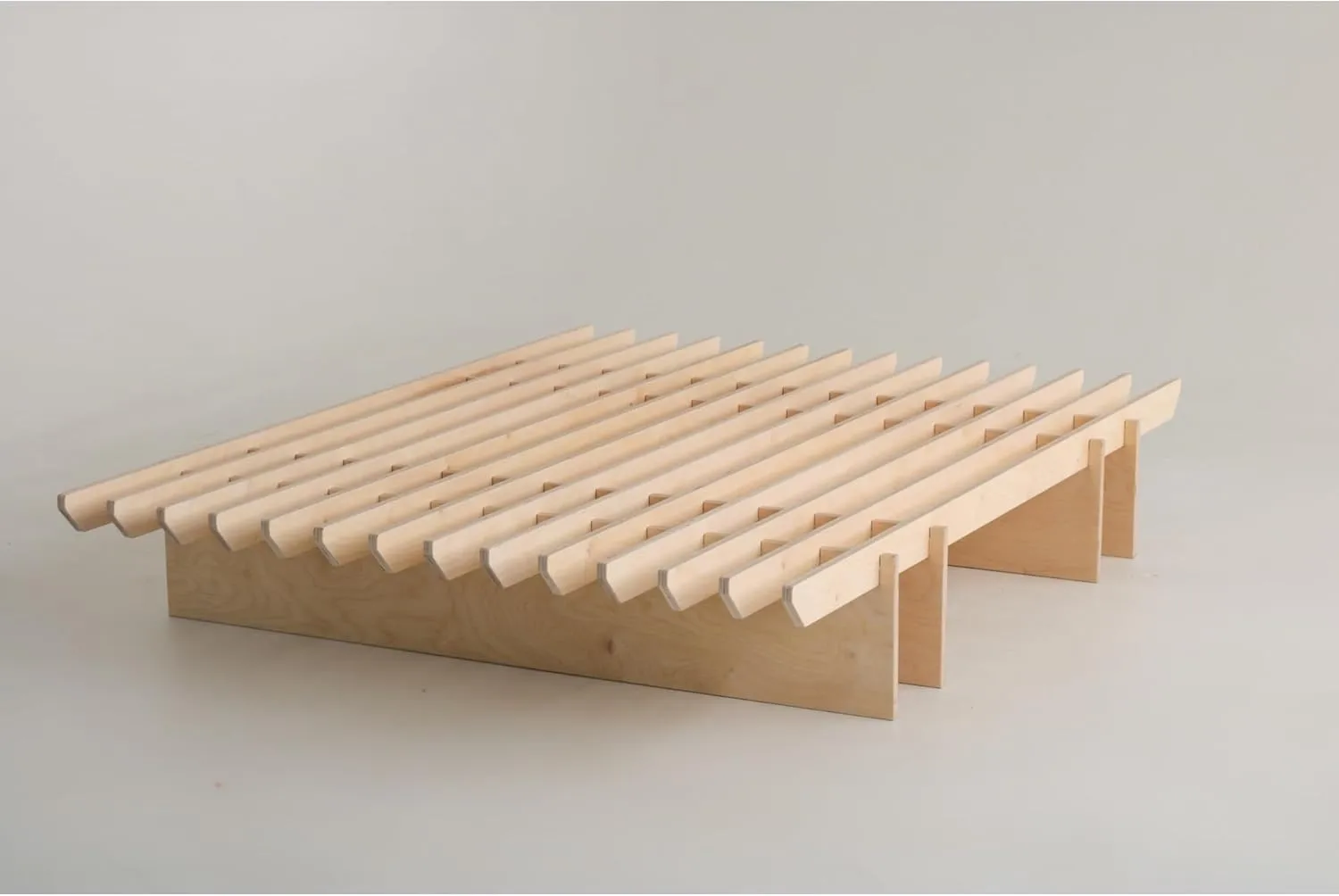

Option 2: Low Profile Frame

Next, I considered a more modern low-profile frame, also sourced from Etsy. This version used long horizontal slats paired with thinner vertical supports. Although the design was lighter and simpler, I was unsure about the strength of 19mm vertical members and imagined supplementing them with off-cuts. Estimated cost: $325.

Additional Influence

Another frame caught my eye for its broad, grounded stance and symmetry. While beautiful, the materials and joinery involved would’ve pushed the budget past what I felt comfortable spending.

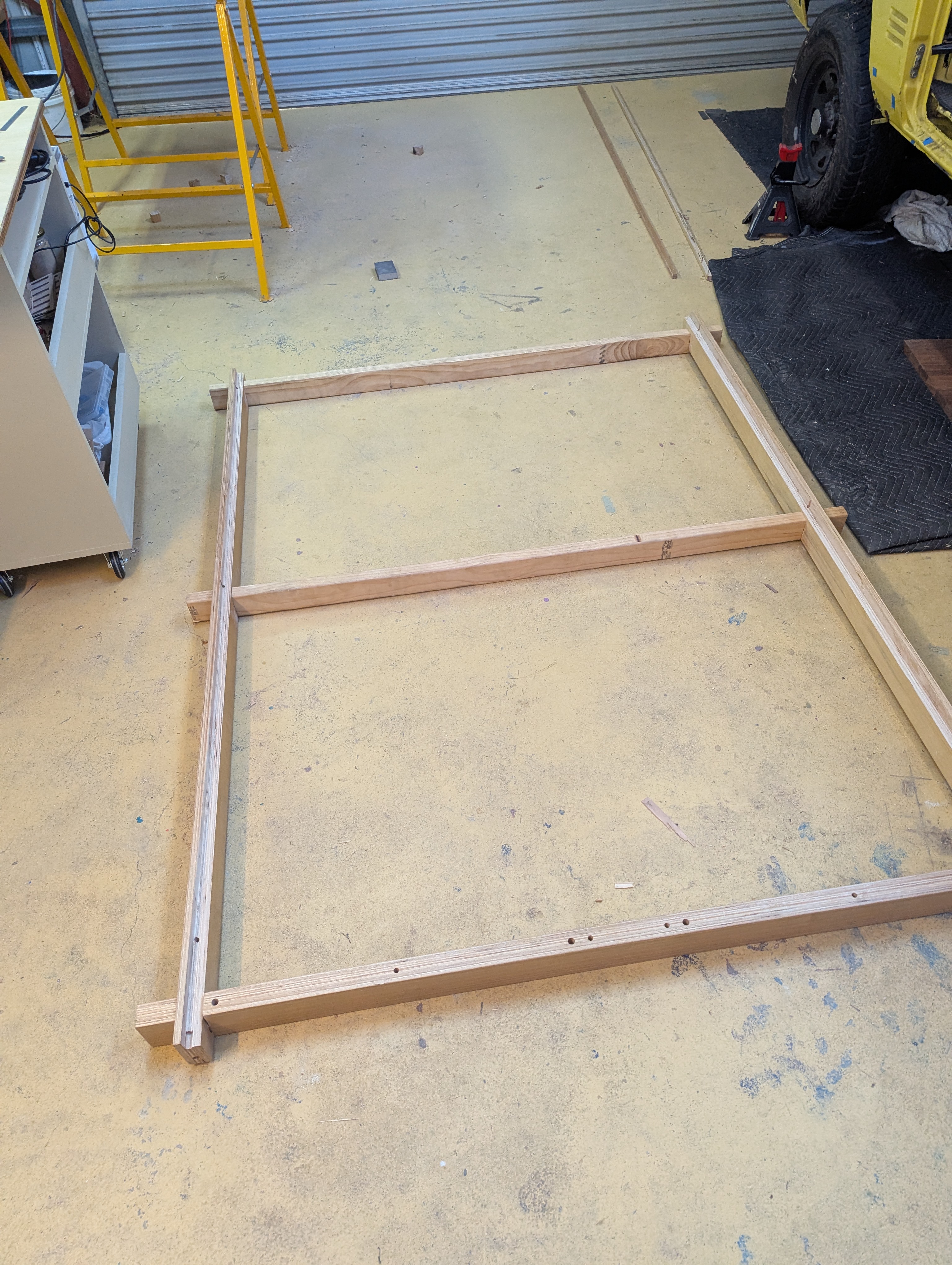

♻️ Final Build: Salvaged Material Approach

Instead of buying everything new, I pivoted to a salvaged build using materials from an old bed frame and off-cuts in the workshop. This decision drastically reduced costs while keeping the aesthetic and structural integrity I wanted. I carefully measured and sorted available pieces, prioritizing strong, non-treated pine and hardwood components.

The key parts included:

- Long support slats (1426mm length, 17 total)

- Two 2640mm beams and two 2070mm thick beams for the main structural rails

- A shorter 2010mm beam used to reinforce the center

🧰 Construction Process

Using a table saw and pull saw, I shaped and cut each piece to size. For joinery, I chose dado cuts — shallow, square channels along the inner face of vertical rails — to nest the slats securely and evenly without the need for screws or brackets. This created a locked-in box structure that relied purely on friction and weight distribution.

Midway through, I realized that the central section needed additional reinforcement. A beam was added lengthwise down the center to prevent sagging under pressure — a simple but essential adjustment. No finishing oils or paints were used; I wanted to keep the surface as natural and breathable as possible.

💰 Cost & Materials

Because I used mostly salvaged wood, the cost was minimal. Compared to the earlier design estimates of $325 to nearly $500, this version cost a fraction — mostly time, effort, and precision. There’s a quiet satisfaction in making something functional and beautiful from leftover material.

✅ Outcome

The bed frame turned out exactly as I hoped. It’s sturdy and minimalist. More importantly, shaped by necessity, built with intention. The entire process, from planning to final assembly, took about a day.